30

Nov 2020

The integral retro-design of the electronic card

The integral retro-design of the electronic card

Expert in the field of electronics, our electronic CAO design office Expert PCB, provides you with its know-how for the realization of subcontracting in prototype and series and the redesign of your electronic card.

The challenge

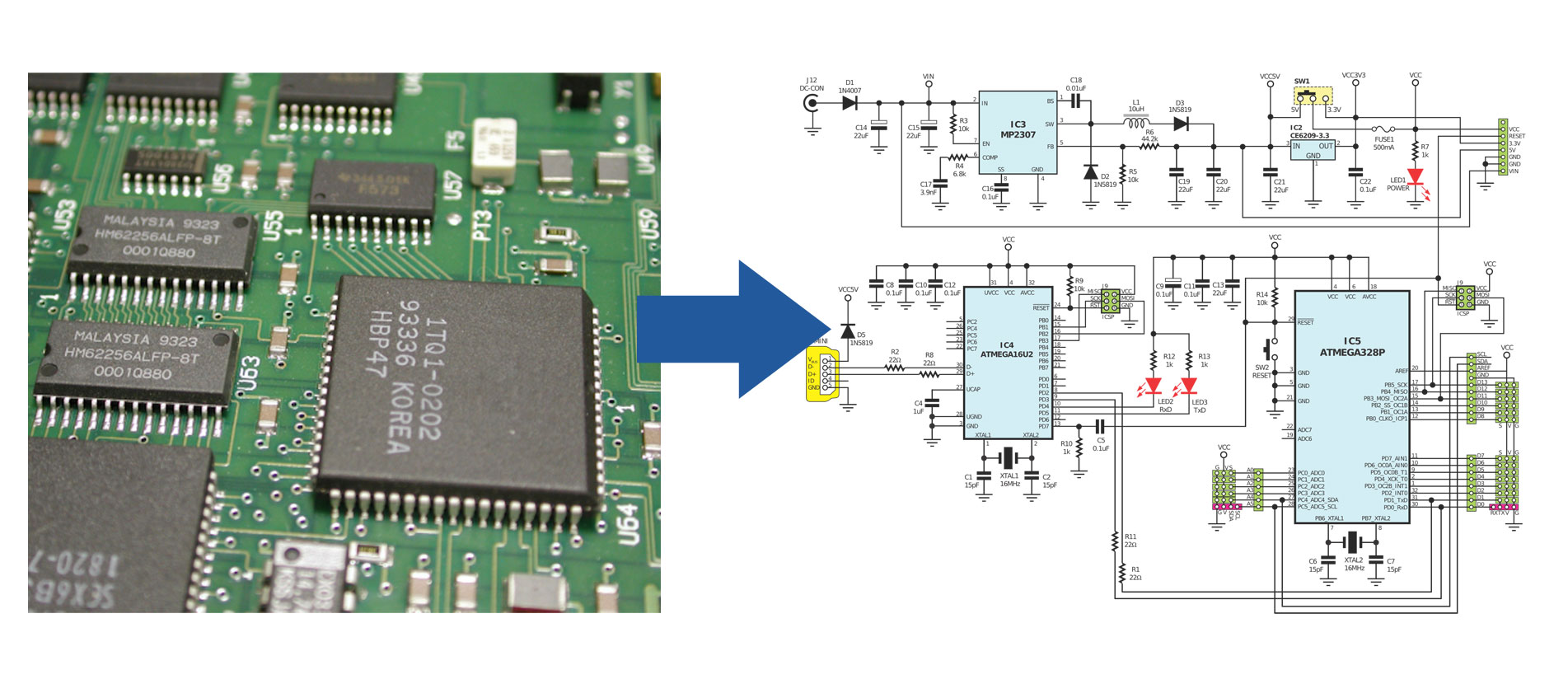

You have to re-manufacture or archive an electronic card, but you no longer have the digital data necessary to launch a new production. However, you still have a few copies of the circuit.

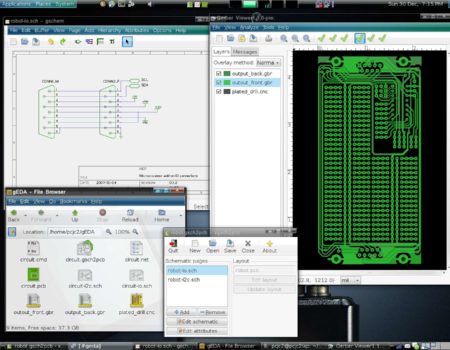

Whatever the case, we have the tools based around dedicated scanning software. And powerful CAD / CAM stations, which allow us to recreate all the files necessary for a new production.

The system

The software is coupled with a high resolution scanner which allows the exact and functional reproduction of the original documents. Sources can be; silver films, paper, diazos or chrome on glass but also bare printed circuits, flex, ceramics …

Regarding bare or wired printed circuits, we know how to treat both single-sided circuits and multilayer circuits (by proceeding by successive delamination of the internal layers). The presence of blind or buried holes will be managed.

Our CAD / CAM stations allow us to carry out all the checks before manufacturing (DRC, bezels, manufacturing class, etc.). And perform an electrical test comparison between the generated data and a reference circuit.

In the case of a multi-layer printed circuit in one copy, a list of the equipotentials will be noted before any intervention.

The final dossier will be provided in the manufacturing data format as well as other more generic formats such as PDF or DXF. We will also be able to generate the solder paste files as well as the placement files for the CMS or feedthrough components. Including orientation, nomenclature or your internal references.

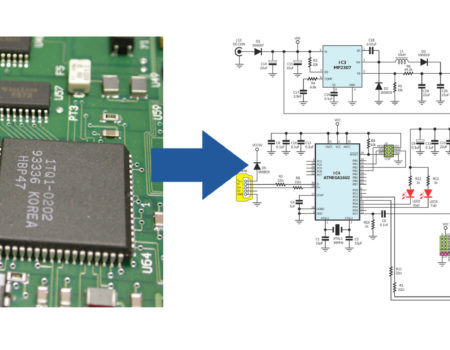

Our electronic CAD design office carries out the complete reverse engineering of your electronic card through the following steps:

Schematic: on condition that you have identified the location of all the components on the card and that you have numbered the tabs. An electrical diagram can also be reconstructed and provided in a smart PDF format that will allow you to highlight each signal.

Equipment plan: if you have a wired card, we can establish a nomenclature. Record the equipment plan, then unwire the card for processing.

Manufacturing: our service providers can also include the manufacture of new printed circuits.

Obsolescence: we are also able to search for replacement components for obsolete ones. This information is returned at the digitization level. And if necessary changes are made to the layout of the card.

Our other posts