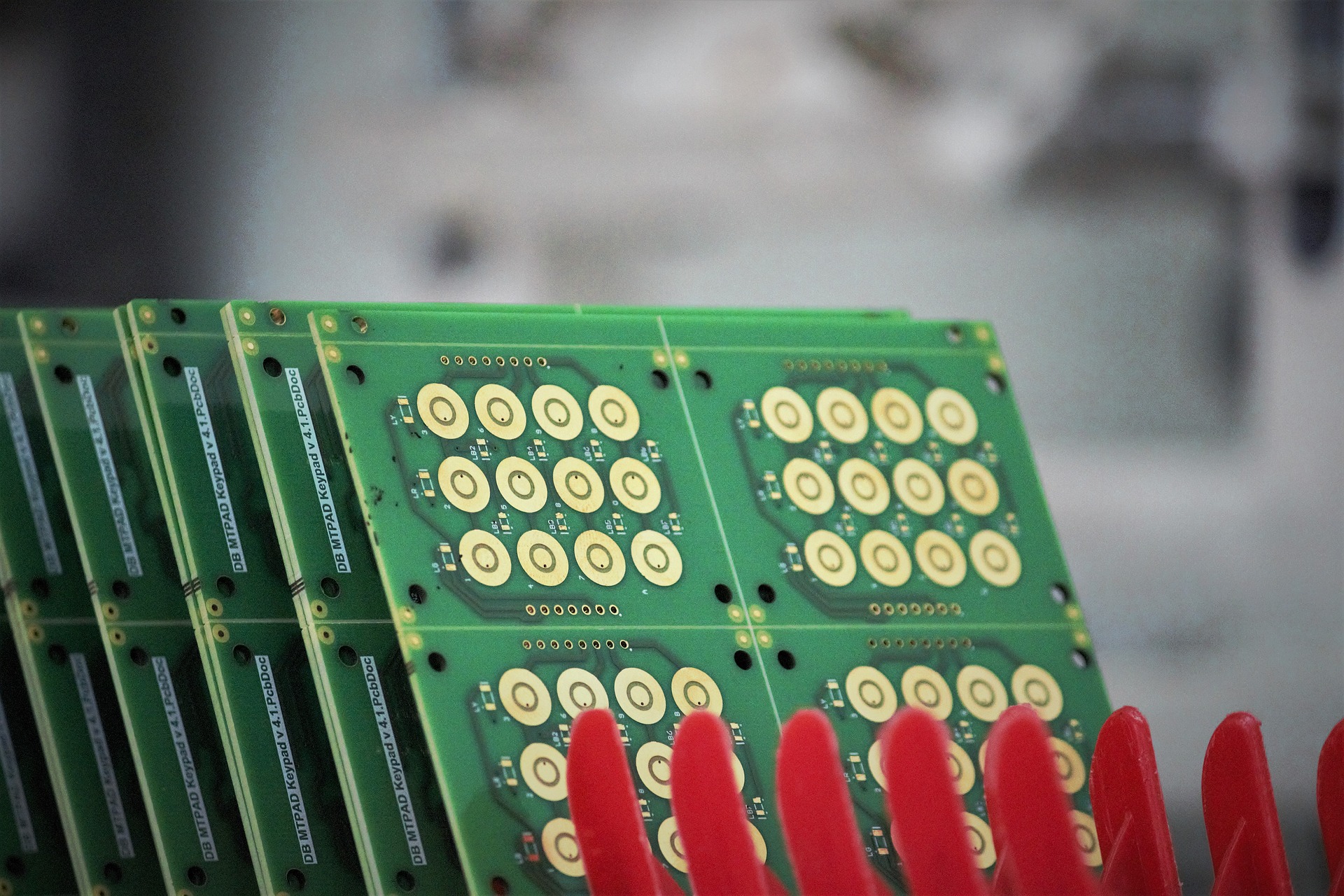

Thanks to our skills, You can outsource the wiring of your electronic boards manufacturing needs to us.

Whether for prototypes, small or large series, we offer production plans adapted to the objectives of our customers. Our commitment: to offer a quality offer that is kept in cost and time.

We strive at all times to promote “made in France” to participate at our level in the competitiveness of our country and to promote exchanges with our customers and local partners.

TO ENSURE THE ACHIEVEMENT OF

YOUR PRODUCTS, WE OFFER:

PCB EXPERT:

A QUALITY ELECTRONIC SERVICE

Each project is specific to its promoter and its market. This is why, at Expert PCB, we have developed this process which we follow systematically to guarantee an irreproachable quality of service.

We are adept at Agile / Scrum methods which are easily applied within our human structure. Design iterations and optimizations are then quick and relevant.

Subcontracting: Layout PCB Design and EMS

From the Layout PCB design to electronic production and industrialization, our added value is measured at all stages of your project. We consider all the requirements of your project and we are always a source of proposals for the success of our collaborations oriented “Industry B2B” but also “Mass Market B2C”.

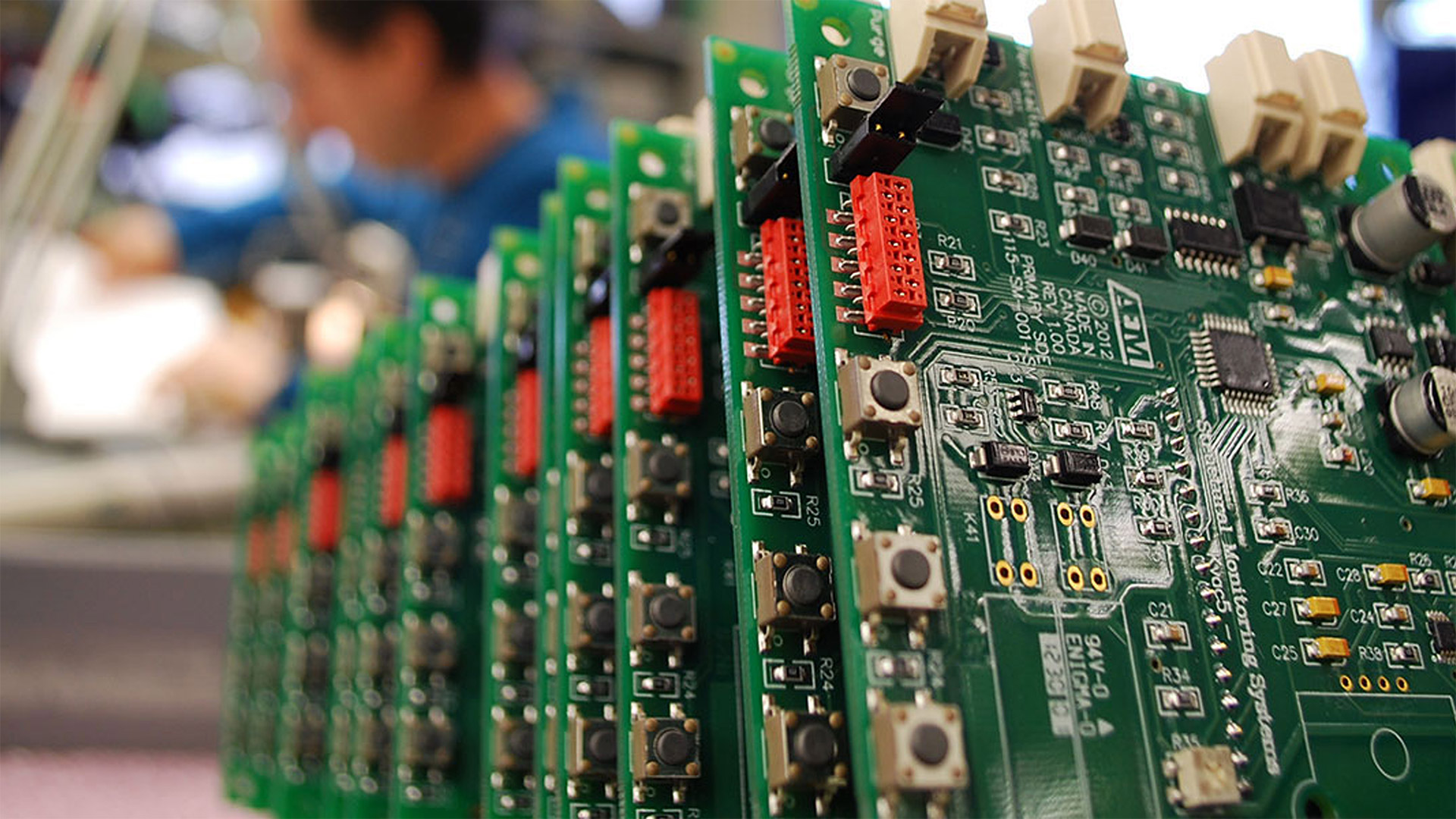

Offering global engineering services, Expert PCB completes its offer with an electronic subcontracting service where we ensure the assembly of your complete electronic products through our international production network.

Expert PCB can thus produce your prototypes but also larger series according to qualified professional industrial channels via our regional and international partners, always perfectly meeting the requirements of quality, deadlines and costs.

Prototypes and Industrialization

The transfer of your project from the electronic prototype stage to that of mass production, traditionally recognized as being difficult and extremely complex, is mastered and controlled thanks to Expert PCB. All you have to do is take advantage of our network of partners and our know-how.

Thanks to our network, with Expert PCB you have the opportunity to:

- The manufacturing of electronic boards in small or large series: Prototype mode, CMS report line mode, etc.

- The manufacture of plastic parts, sheet metal work, etc.

- Mechatronic assembly for the integration of electronic boards into their casings

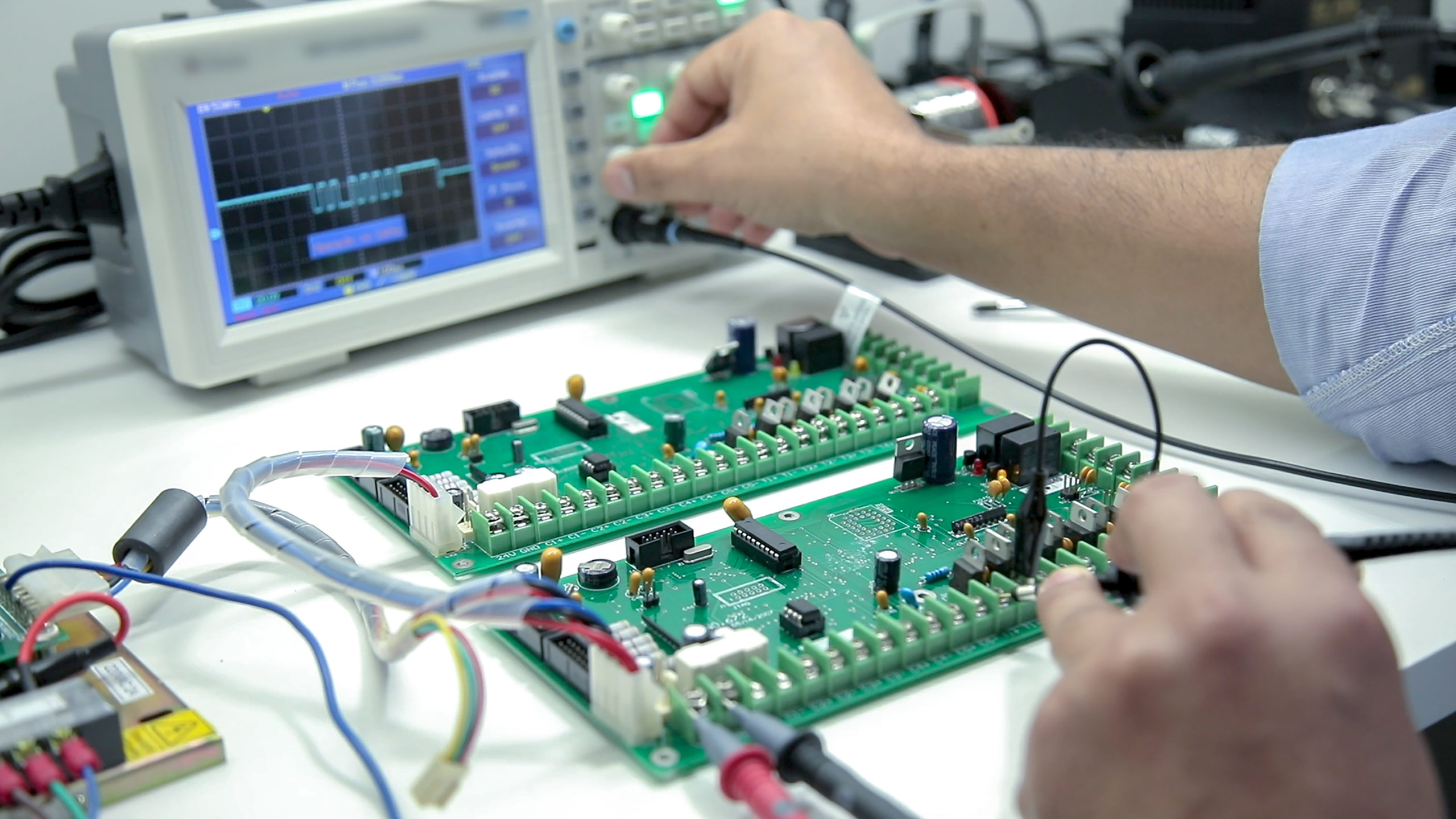

Quality checkpoint

In order to provide the most complete solution possible, we offer our customers the production of test benches and technical strands. These are 19-inch type racks and bays integrating all electrical and electronic equipment to ensure testing and development of industrial products. We define and produce the mechanical supports adapted to the products to be tested, nail bed type bases and connecting strands to the racks and racks (with programming in Labview or LabWindows, CVI if necessary.)

- Realization of strands, cables, wrapping and specific wiring.

- Integration into racks, racks and other enclosures.

- Bending, machining of mechanical parts.

- Management of kitting and logistics.

- Complete management of manufacturing files – Very good report Reliability / Service / Cost.

EXPERT PCB OFFERS YOU THE BEST IN ELECTRONIC SERVICES

Because our customers today face increasingly drastic market demands, time-to-market is a key success factor. We offer an electronic boards production service for the prototyping phase in the shortest possible time. Our purchasing department processes and organizes supplies in order to achieve logistics related to components. When the development is validated, we adapt our offer for the switch to pre-series and automatic line.

Our people and our processes are RoHS-compliant and we are committed to providing you with ideas and solutions to improve your product definitions through feedback from our production department.